热缩管分类

联系我们

南京沃杰新材料有限公司

联系人:徐先生

手机:18912778693

电话:0512-65980871

传真:0512-65980872

邮箱:ly@szwoje.com

地址:苏州市吴中区迎春南路94-2号

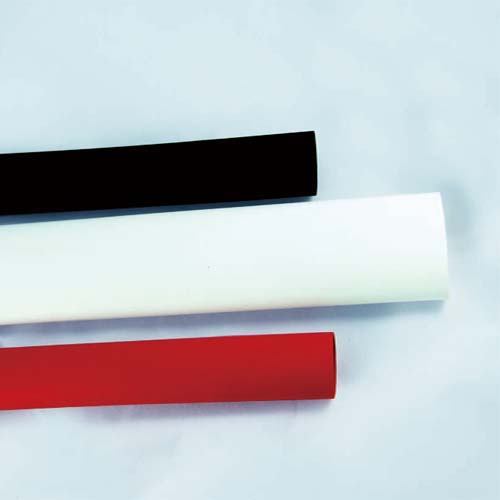

南京半硬带胶中壁管

【产品介绍】半硬带胶中壁管由半硬聚烯烃材料和热熔胶双层构成,外层具有优异的电气绝缘性能和耐磨、耐冲击性能,内层具有密封防水的功能,广泛应用于中低压电力、通信、机械等领域。【产品特点】1、半硬、环保2、起缩温度:≥80℃3、终缩温度:≥120℃4、使用温度:-55℃-110℃4、标准颜色:黑色【聚烯烃外层技术指标】性能指标测试方法/条件拉伸强度≥14MPaASTMD2671断裂伸长...

联系电话:18912778693

【产品介绍】

半硬带胶中壁管由半硬聚烯烃材料和热熔胶双层构成,外层具有优异的电气绝缘性能和耐磨、耐冲击性能,内层具有密封防水的功能,广泛应用于中低压电力、通信、机械等领域。

【产品特点】

1、半硬、环保

2、起缩温度:≥80℃

3、终缩温度:≥120℃

4、使用温度:-55℃-110℃

4、标准颜色:黑色

【聚烯烃外层技术指标】

【热熔胶内层技术指标】

【结构示意图】

【规格表】

注:可按顾客要求订制特殊尺寸及包装

半硬带胶中壁管由半硬聚烯烃材料和热熔胶双层构成,外层具有优异的电气绝缘性能和耐磨、耐冲击性能,内层具有密封防水的功能,广泛应用于中低压电力、通信、机械等领域。

【产品特点】

1、半硬、环保

2、起缩温度:≥80℃

3、终缩温度:≥120℃

4、使用温度:-55℃-110℃

4、标准颜色:黑色

【聚烯烃外层技术指标】

| 性能 | 指标 | 测试方法/条件 |

| 拉伸强度 | ≥14MPa | ASTM D 2671 |

| 断裂伸长率 | ≥400% | ASTM D 2671 |

| 热老化后拉伸强度 | ≥12MPa | 150℃×168h |

| 热老化后断裂伸长率 | ≥300% | 150℃×168h |

| 轴向变化率 | 0~-10% | ASTM D 2671 |

| 阻燃性 | 非阻燃 | - |

| 击穿强度 | ≥18kV/mm | IEC 60243 |

| 体积电阻率 | ≥1013Ω.cm | IEC 60093 |

【热熔胶内层技术指标】

| 性能 | 指标 | 测试方法/条件 |

| 软化点 | 85±5℃ | ASTM E 28 |

| 吸水率 | <0.5% | ASTM D 570 |

| 剥离强度(胶对PE) | ≥120N/25mm | ASTM D 1000 |

| 剥离强度(胶对铝) | ≥80N/25mm | ASTM D 1000 |

【结构示意图】

【规格表】

| 规格 | 供货内径D(mm) | 全缩后尺寸(mm) | 标准包装 | |

| 内径d | 壁厚w | (米/根) | ||

| Φ8.0/2.0 | ≥8.0 | ≤2.00 | ≥1.7 | 1.00~1.50 |

| Φ9.0/3.0 | ≥9.0 | ≤3.00 | ≥1.8 | 1.00~1.50 |

| Φ12.0/3.0 | ≥12.0 | ≤3.00 | ≥1.8 | 1.00~1.50 |

| Φ16.0/5.0 | ≥16.0 | ≤5.00 | ≥2.0 | 1.00~1.50 |

| Φ19.0/5.0 | ≥19.0 | ≤5.00 | ≥2.2 | 1.00~1.50 |

| Φ22.0/6.0 | ≥22.0 | ≤6.00 | ≥2.2 | 1.00~1.50 |

| Φ28.0/6.0 | ≥28.0 | ≤6.00 | ≥2.5 | 1.00~1.50 |

| Φ33.0/8.0 | ≥33.0 | ≤8.00 | ≥2.5 | 1.00~1.50 |

| Φ40.0/12.0 | ≥40.0 | ≤12.0 | ≥2.5 | 1.00~1.50 |

| Φ45.0/12.0 | ≥45.0 | ≤12.0 | ≥2.5 | 1.00~1.50 |

| Φ55.0/16.0 | ≥55.0 | ≤16.0 | ≥2.7 | 1.00~1.50 |

| Φ65.0/19.0 | ≥65.0 | ≤19.0 | ≥2.8 | 1.00~1.50 |

| Φ75.0/22.0 | ≥75.0 | ≤22.0 | ≥3.0 | 1.00~1.50 |

| Φ85.0/25.0 | ≥85.0 | ≤25.0 | ≥3.0 | 1.00~1.50 |

| Φ95.0/30.0 | ≥95.0 | ≤30.0 | ≥3.0 | 1.00~1.50 |

| Φ115.0/34.0 | ≥115.0 | ≤34.0 | ≥3.3 | 1.00~1.50 |

| Φ140.0/42.0 | ≥140.0 | ≤42.0 | ≥3.5 | 1.00~1.50 |

| Φ160.0/50.0 | ≥160.0 | ≤50.0 | ≥3.5 | 1.00~1.50 |

| Φ180.0/58.0 | ≥180.0 | ≤58.0 | ≥3.5 | 1.00~1.50 |

| Φ205.0/65.0 | ≥205.0 | ≤65.0 | ≥3.5 | 1.00~1.50 |

| Φ235.0/65.0 | ≥235.0 | ≤65.0 | ≥3.7 | 1.00~1.50 |

| Φ265.0/75.0 | ≥265.0 | ≤75.0 | ≥4.0 | 1.00~1.50 |

| Φ300.0/85.0 | ≥300.0 | ≤85.0 | ≥4.0 | 1.00~1.50 |

| Φ350.0/100.0 | ≥350.0 | ≤100.0 | ≥4.3 | 1.00~1.50 |

| Φ380.0/150.0 | ≥380.0 | ≤150.0 | ≥4.3 | 1.00~1.50 |

| Φ410.0/150.0 | ≥410.0 | ≤150.0 | ≥4.3 | 1.00~1.50 |

上一篇:环保双壁管

下一篇:3:1柔软厚胶低温收缩双壁管

相关产品